topic area Ex-protected

When is it necessary to use an Ex light?

If there is a risk of an explosive atmosphere occurring or being present, the use of an Ex light is necessary.

What is an explosive atmosphere?

An explosive atmosphere is a mixture of air under atmospheric conditions and flammable substances in the form of gases, vapors, mists or dusts, in which combustion spreads throughout the unburned mixture after ignition. In a potentially explosive atmosphere, the atmosphere may become explosive due to local and operational conditions can become explosive.

Which substances can form an explosive atmosphere with air?

Flammable or combustible liquids, gases or solids can form an explosive atmosphere. Solids must have a small particle size (usually < 0.5 mm) in order to burn explosively.

Typical solids are flour, wood, coal, but the dust of many plastics and metals can also be ignited.

Examples of gases are acetylene, methane, ammonia, petrol, diesel, hydrogen, propane and natural gas.

What are possible ignition sources?

Possible ignition sources include:

- hot surfaces

- Flames and hot gases

- electrical equipment

- mechanically generated sparks

- static electricity

- electrical equalizing currents/cathodic corrosion protection

- chemical reactions

- ultrasound

- electromagnetic fields and radiation

- lightning

- ionizing radiation

- adiabatic compression

What is an explosion?

An explosion is an oxidation or decomposition reaction that takes place at a high reaction rate and causes an increase in temperature or pressure (up to 10 bar for gases and vapors, up to 14 bar for dusts) or both at the same time. These are reactions of combustible gases, mists and vapors or dusts and combustible fluff with the oxygen in the air.

Why is a dust explosion so dangerous?

In a dust explosion, combustible dust particles ignite. The pressure created by the combustion often causes further dust to be whirled up and ignited, causing the explosion to spread like an avalanche. (YouTube Video available in german)

In which typical areas are Ex lights required?

Ex luminaires are primarily required in the following areas:

- chemical factories

- refineries

- paint factories

- paint shops

- mills

- cleaning plants

- Warehouses for ground products

- Tank and loading stations for flammable gases and liquids

- and much more

What parameters can I use to select the required Ex luminaire when flammable gases or dusts are present?

To select the right Ex luminaire, you first need the Ex zone, which determines the device group and the required device category of the luminaire. For explosive gas atmospheres, the temperature class and the device subgroup (IIA, IIB, IIC) are required; for explosive dust atmospheres, the maximum permissible surface temperature and the device subgroup (IIIA, IIIB, IIIC) are required. In addition, environmental parameters such as the temperature range and chemical influences are required.

What are the different Ex zones?

Potentially explosive atmospheres are divided into the following zones depending on the probability of an explosive atmosphere occurring:

Gases, vapors and mists

- Zone 0 - areas in which an explosive atmosphere consisting of a mixture of air and flammable gases, vapors or mists is present continuously or for long periods or frequently.

- Zone 1 - Areas in which an explosive atmosphere occasionally occurs during normal operation.

- Zone 2 - Areas in which an explosive atmosphere occurs only rarely and then only briefly during normal operation.

Dusts and combustible fluff

- Zone 20 - Places in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously or for long periods or frequently.

- Zone 21 - Places in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally.

- Zone 22 - Places in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation but, if it does occur, will persist for a short period only.

You will find a large selection of luminaires and accessories for zones 1/21 and 2/22 in our product portfolio.

Please note that the classification of an area into the respective zone is the responsibility of the operator. We at SCHUCH are not permitted to make any recommendations or classifications.

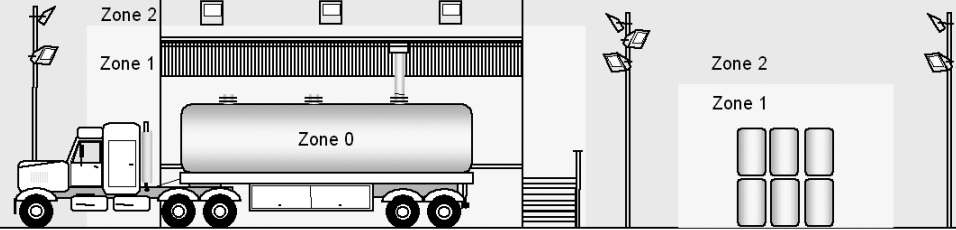

Typical examples of zone categorisation for flammable liquids

Who can tell me whether, and if so, which Ex zone applies in my specific case?

Specialized service providers, employers' liability insurance associations, occupational health and safety authorities or monitoring bodies can help with the classification.

What are device groups?

A distinction is made between two equipment groups:

- Equipment group I - Equipment for use in underground mines and their surface installations

- Equipment group II - All other equipment for use in potentially explosive atmospheres

What are equipment categories?

In line with the different zones, equipment assigned to equipment group II is divided into three different categories:

- Category 1 - Devices that ensure a very high level of safety

- Category 2 - Appliances still have a high level of safety

- Category 3 - Appliances that guarantee a normal level of safety

The relevant marking can be found on the equipment, followed by a letter G and/or D. The letter G stands for explosive gas atmosphere, the letter D stands for explosive dust atmosphere.

What is the relationship between equipment group, category and zone?

| Zone | Equipment group | Equipment category |

| 0 | II | 1G |

| 1 | II | 2G and 1G |

| 2 | II | 3G, 2G and 1G |

| 20 | II | 1D |

| 21 | II | 2D and 1D |

| 22 | II | 3D, 2D and 1D |

What does the temperature class mean?

An important parameter for the classification of gases is the ignition temperature. The ignition temperature is the lowest temperature value of a hot surface at which an explosive atmosphere can ignite. The maximum surface temperature of a luminaire must always be lower than the ignition temperature of the gas, mist or vapor/air mixture present. The maximum surface temperature of the luminaire is indicated by the temperature class.

| Temperature class | Maximum permissible surface temperature [°C] | Ignition temperature range of the mixtures [°C] |

| T1 | 450 | > 450 |

| T2 | 300 | > 300 ≤ 450 |

| T3 | 200 | > 200 ≤ 300 |

| T4 | 135 | > 135 ≤ 200 |

| T5 | 100 | > 100 ≤ 135 |

| T6 | 85 | > 85 ≤ 100 |

What is an appliance subgroup?

Appliances for explosive gas atmospheres are divided into subgroups IIA, IIB and IIC depending on the ignitability of the gases. Substances in equipment subgroup IIC require the lowest energy for ignition, substances in IIA the highest.

Devices for dust explosive atmospheres are classified in subgroups IIIC for conductive dusts (specific electrical resistance ≤ 1kΩ m), IIIB for non-conductive dusts (specific electrical resistance > 1kΩ m) and IIIA for fluff and fibers.

Can I also use Ex luminaires for Zone 1/21 in Zone 2/22?

Category 2G and 2D (Zone 1/21) Ex luminaires can also be used in Zone 2/22.

What do the types of protection "increased safety" and "flameproof enclosure" mean, in which Ex luminaires are predominantly built?

With the "increased safety" type of protection, ignition sources of the equipment are avoided. Measures are taken to prevent the possibility of impermissibly high temperatures and the occurrence of sparks or arcs with an increased level of safety.

In "flameproof enclosures", parts of the equipment that could ignite an explosive atmosphere are enclosed in a housing. The explosive mixture can penetrate the enclosure and ignite. However, transmission to the outside is prevented by the special design.

What are the advantages of the "increased safety" type of protection compared to "flameproof enclosure"?

The "increased safety" type of protection usually enables a more economical design with simplified maintenance. The lower weight is also advantageous for installation.

Topic Area outdoor

What is the difference between a power reduction with or without control phase?

Power reduction with control phase (LR)

A power reduction with control phase (LR) uses a control line to dim the luminaire. If the control phase is switched on, the luminaire luminous flux is 100%. When the control phase is switched off, the luminaire dims to 50% luminous flux. Other dimming levels (10%-90%) and an inverse function of the control phase (reduced operation 50% when the control phase is connected) are optionally available.

Power reduction without control phase (LA)

If no control phase is available, a luminaire with autonomous power reduction (LA) can be used. The luminaire dims completely independently to different levels (between 10% and 90%) at programmed times. Several dimming levels per night are possible. Standard: One dimming level, 50% luminous flux from 22:00-04:00 CET and 23:00-05:00 CEST.

Why is it not advisable to control outdoor luminaires with power reduction without a control phase using a timer?

Luminaires with independent power reduction (LA) receive their time signal exclusively via the switch-on and switch-off times of the luminaire. If the luminaire is switched on at times other than dusk and switched off at dawn (using a twilight switch), the calculation of the specified dimming times cannot be carried out correctly. This can result in incorrect dimming behavior: The power reduction does not occur at all or occurs irregularly and at greatly deviating times.

What is meant by the term "constant luminous flux function"?

LED light sources are characterized by a gradual decrease in luminous flux (see also "What decrease in luminous flux (degradation) is to be expected with LED luminaires during their service life?"). A constant luminous flux function compensates for this decrease so that the luminaire emits a constant luminous flux over its entire service life.

SCHUCH luminaires with a constant luminous flux function (CL) are initially set to approx. 90% of the output compared to basic types without CL. The luminous flux remains constant over the entire service life. The output increases from 90% to a maximum of 100% at the end of the service life. After this time, the luminous flux degradation is no longer compensated for by an increase in output.

What is meant by "photobiological safety" of LED luminaires?

The photobiological safety of luminaires is dealt with in the standard DIN EN 62471:2009. It describes limit values and risk groups for irradiation as well as corresponding measurement methods in the UV, visible and infrared spectral range. The protection objective is to exclude both thermal and photochemical hazards to the human eye and skin.

Almost all Schuch luminaires fall into the lower lower risk groups 0 and 1. They cannot cause any photobiological damage to the eye or human skin and are therefore harmless.

Luminaires that fall into risk group 2 are marked with a picture symbol ("do not look into the light source"). The installation instructions also indicate the distance at which it is safe to look into the light. Due to the installation location, a hazard can be ruled out for most technical luminaires in risk group 2, as it is not possible to look into the luminaire from a short distance. Doubling the distance reduces the radiation reaching the eye to a quarter (square law of distance). In most cases, therefore, caution is only required during maintenance work.

Luminaires in risk group 3 cannot be approved as they would pose a significant risk.

Why do you need increased surge protection for outdoor lights?

LED outdoor luminaires and outdoor luminaires with electronic ballasts for conventional lamps are significantly more sensitive to overvoltage events than luminaires with conventional ballasts. Overvoltages of up to approx. 6kV can occur in the mains due to switching operations/load changes. Lightning strikes in the vicinity of outdoor lighting systems can cause voltages of up to a multiple of 10kV, depending on the distance of the strike to the luminaire and the conductivity in the ground. In the case of direct lightning strikes in a street light, the pulse heights occurring are so high that there is no economically justifiable protective measure.

The electronic ballasts used by SCHUCH already have an increased surge voltage resistance. An additional overvoltage protection module (OP) in the luminaire or in the cable junction box can further increase the surge voltage resistance of the luminaire. Surge protection modules, which disconnect the luminaire from the mains in the event of a fault, offer even greater operational safety.

Why can't outdoor luminaires in protection class II be easily mounted on wooden, concrete and plastic poles, on house walls or cable suspensions?

When outdoor luminaires are mounted on wooden, concrete or plastic poles, they are very well insulated from the ground. In outdoor areas, air movements can cause static charges that destroy the ECG in the luminaire. The same applies to cable luminaires if the cables are attached to walls, for example.

What do I need to consider when using LED outdoor luminaires near the sea?

LED outdoor lights often have aluminum housings or at least housing parts made of aluminum. When installed near the sea, there is a risk of corrosion occurring despite a high-quality paint finish. Paint damage that occurs during installation is particularly critical.

Schuch offers so-called seawater-resistant versions (SWP) for these operating conditions. The luminaire housings or parts are first primed with a special paint and then powder-coated. This significantly improves resistance to a salty atmosphere. At the same time, the primer prevents infiltration of the paintwork in the event of paint damage.

Can the dimming profile for night-time dimming be subsequently changed for luminaires with power reduction?

Please contact us. The control gear can be reprogrammed with the appropriate hardware and software.

Can outdoor luminaires be retrofitted with glare control?

For some SCHUCH ranges, shields on the building side that enable glare control on the rear of the luminaires are available as accessories. These are listed in the data sheet of the respective article under "Optional accessories".

What is the difference between ULOR and ULR?

ULOR is the abbreviation for Upward Output Light Ratio. ULOR indicates the relative proportion of light emitted by a luminaire into the upper half-space. A horizontally aligned luminaire is always assumed (inclination 0°). In practice, luminaires are often tilted upwards. The inclination increases the proportion of light emitted into the upper half-space.

To distinguish this value from the catalog specification for a luminaire without inclination, the designation ULR (Upward Light Ratio) was chosen for mounted luminaires. The ULR must always be used to evaluate a lighting system.

In the special case where a luminaire cannot be tilted (e.g. mushroom luminaires), the values for ULOR and ULR are identical.

When do we speak of light emission - when of light immission?

The term Emission is derived from the Latin word emittere (to send out). Consequently, light emission refers to the light emitted by a luminaire.

The term Immission is derived from the Latin word immittere (to send in). Consequently, light immission refers, for example, to the light that is (undesirably) emitted into a bedroom, the surroundings of a sports facility or a nature reserve.

Topic Area Indoor

Why can condensation form inside the luminaire in damp-proof luminaires with a high protection rating?

Luminaires with an IP65/IP 66 protection rating are not hermetically sealed. If these luminaires are used in a damp environment, condensation may form. When switched on, the inherent heat of the luminaire creates an overpressure that slowly dissipates during operation. When the light is switched off, a negative pressure is created as the light cools down. When this negative pressure is reduced, moist air is drawn into the inside of the luminaire. The moisture condenses in the luminaire. The amount of moisture drawn in increases with the number of switch-on/switch-off cycles. Due to the high protection rating of the luminaire, the moisture can no longer escape. This can be remedied by using pressure equalization elements. The membrane keeps water away from the inside of the luminaire, but allows water vapor to pass through. The luminaire can breathe through the membrane. Moisture that is sucked in evaporates during operation of the luminaire and can escape again through the membrane. It is essential that the luminaires have a sufficiently long operating time. When installing on cold ceilings, it is also important to ensure that spacers are used.

Can I also use damp-proof luminaires with IP 65 protection outdoors?

If damp-proof luminaires with an IP 65 protection rating are to be used outdoors, the luminaires must be modified and approved for this purpose. Schuch also offers almost all damp-proof luminaires in so-called AUS versions. All external parts are UV-resistant and the luminaires are equipped with cable glands and pressure equalization elements. This prevents condensation from forming in the long term. Sufficient duty cycle must be ensured.

See also: Why can condensation form inside the luminaire in damp-proof luminaires with a high protection rating?

What does the D marking mean?

Luminaires with the D marking have a limited surface temperature. On surfaces on which dust or fibers can be deposited, the surface temperature is limited to 90°C in normal operation and 115°C in the event of a luminaire fault. This prevents flammable dust or combustible fibers deposited on the luminaire from igniting. Luminaires with the D mark have a minimum protection rating of IP 54 and are tested in accordance with the EN 60598 Part 2-24 standard. The D marking replaces the FF marking previously used in Germany.

When do I have to use lights with the D mark?

In areas at risk of fire (e.g. in paper and wood processing or in agricultural premises), only luminaires that comply with the requirements of DIN EN 60598-2-24 and are marked D may be used. They must always be used if combustible dusts and fibers are present at the installation site (see also VdS Guideline 2033 "Electrical installations in operating sites at risk of fire and equivalent risks").

Caution: Similar to gases, mists and vapors, all combustible dusts and fluff can also react explosively under certain conditions. In these cases, explosion-proof luminaires must be used.

What are noxious gases and where do they occur?

Gases that have a corrosive effect are known as noxious gases. Such gases can damage plastics and decompose metals. They occur in many different ways. Many industrial processes are accompanied by noxious gases. But they can also occur, for example, in sewage treatment and composting plants, in agriculture, in tire production and storage and in swimming pools.

Why can LED luminaires not be used without hesitation in environments contaminated with harmful gases or corrosive substances?

Depending on the substance, concentration, temperature and duration of exposure, harmful gases and other corrosive substances can cause damage to LED luminaires, including total failure:

- Increased degradation (decrease in luminous flux)

- Failure of the LEDs

- Oxidized metals

- Corroded plastics

- Failure of other electronic components (e.g. electronic ballast)

Even luminaires with a high protection rating are affected. Corrosive atmospheres can penetrate the luminaires as they are not gas-tight. To prevent damage and expensive total failure of luminaires, we recommend the use of LED luminaires that are specially designed for use in areas exposed to harmful gases:

- XR version - Absolutely gas-tight luminaire

- HR version - high protection against corrosive atmospheres. Luminaires in the AUS HR version are approved for use in outdoor areas of sewage treatment plants, for example

- ER version - Increased protection against corrosive atmospheres. Luminaires in the ER version are approved for use in production facilities and tire warehouses, for example

Our PRIMO XR series is the optimum solution for areas exposed to harmful gases (exception: hazardous areas, exposure to chemicals that corrode PMMA or stainless steel).

Why can LED luminaires not be used safely in livestock farming?

When used in stables, luminaires are contaminated in particular by the harmful gases ammonia and hydrogen sulphide from the animals' excrement. The installed LED modules and their control gear are damaged. We recommend the use of our PRIMO XR LW profile tube luminaire, which is impervious to harmful gases. This prevents aggressive substances from entering the luminaire interior.

The PRIMO XR DIMD version should be used in poultry farming. This luminaire meets the special requirements regarding flicker-free operation as stipulated in the Federal Livestock Farming Ordinance.

Depending on the type of animal, other series in specially protected ER or LW versions can also be used.

Are there silicone-free LED lights?

Most of our LED lights are equipped with silicone seals. For use in paint shops, it is usually sufficient to prove that no paint-wetting substances are emitted. We have luminaires with a LABS certificate in our range for this purpose.

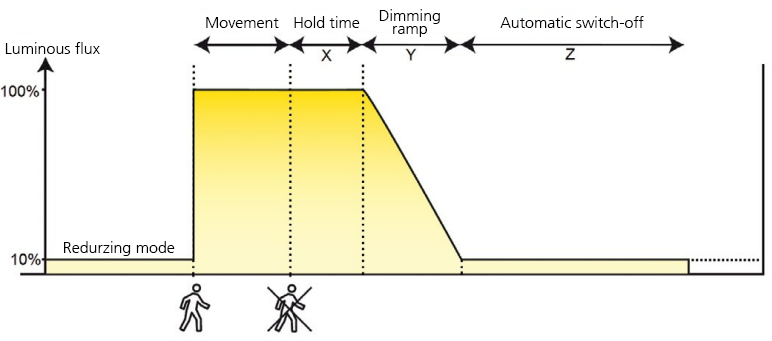

What is the corridor function (DIMC) and when do I need it?

The corridor function enables simple power reduction of luminaires to a fixed value using a standard 230V control voltage. In conjunction with motion detectors or door contacts, high energy savings are possible in rarely used areas.

In the standard setting, the luminaire only provides 100% luminous flux as long as the control phase is active. After deactivating the control phase, the luminaire dims down to the background level of 10% within approx. 30 seconds (due to technical limitations, a higher dimming level is possible for individual versions). As LED modules and control gear only have a limited switching resistance, dimming results in a significantly longer service life of the luminaire compared to switching the luminaire on and off directly (without DIMC). The luminaire never switches itself off, but may be switched off by the user at any time.

The diagram shows the luminous flux output of a luminaire with DIMC that is controlled via a motion detector.

The following standard settings are made for luminaires with DIMC. The parameters can be customized on request:

- Hold time: Luminaire maintains 100% luminous flux for time X after the control phase is switched off (default setting 0 seconds, but the customer can set their own "hold time" by setting the switch-off time delay of their motion detector)

- Dimming ramp: Faster or slower dimming down of the light in period Y (default setting: approx. 30 seconds)

- Automatic switch-off: Light switches off completely after time Z without activity. (Standard setting: never switch off*; versions Z30: light switches off after 30 minutes)

- Background level: Height of the dimming level when there is no activity. (Standard setting: 10%; due to technical limitations, a higher dimming level may apply for individual versions)

Attention:

Luminaires with DIMC designation only do not contain an integrated motion detector as standard, but only the connection for external detectors! When using external motion detectors/sensors, only those with a relay output may be used. Luminaires with internal motion detectors are designated SENS.

Why is the UGR value not a suitable benchmark for glare assessment in industrial lighting?

A distinction is made between 2 types of glare:

- psychological glare

This causes an unpleasant feeling without necessarily being associated with a noticeable reduction in vision.

- physiological glare

This results in a reduction in visual function.

The "United Glare Rating" (UGR) method was developed to standardize the assessment of psychological glare caused by indoor/office lighting worldwide.

In industrial lighting, however, the focus is usually on visual performance and therefore on physiological glare, which is essential for occupational safety and accident prevention.

The UGR method cannot assess physiological glare. Accordingly, it is not taken into account when planning lighting in industrial facilities. The UGR method is therefore not suitable for assessing the glare of lighting systems in industrial applications, especially for hall lighting.

A suitable method must be developed for these applications in the future. The relevant specialist committees in the ZVEI have already taken on this task. (Detailed information: ZVEI position paper „UGR method - application and limits“ / Statement by Prof. Dr. Bruno Weis „Glare assessment in industrial lighting“; Both sources are only available in german)

Topic Area Emergeny

When must safety lighting be installed?

According to the ArBSchG, the employer must carry out a risk assessment to determine whether there are any hazards associated with the employees' work. If the risk assessment shows that a hazard is to be expected if the general lighting fails, safety lighting must be installed.

Can general lighting luminaires be converted into emergency luminaires?

Converting a general lighting luminaire into an emergency luminaire creates a new product. This new luminaire must comply with all technical regulations and statutory provisions that apply to the product, such as RED, LVD, EMC, RoHS, VDE regulations, DIN standards, and a new conformity assessment must be carried out and a new declaration of conformity issued.

The ZVEI's Emergency Lighting Technical Committee therefore recommends using luminaires specially manufactured for emergency lighting applications or luminaires that have been converted and tested on the basis of the required normative regulations and are matched to the planned emergency lighting systems. See „Information on converting general lighting luminaires to emergency luminaires" (ZVEI 05/2019) (Available only in german).

What power supply systems are available?

In general, centralised power supply systems with and without power limitation (CPS, LPS) or self-powered emergency luminaires with a single battery (EB) or electric double-layer capacitors (EDLCs) are used in emergency lighting.

Which battery runtimes are required in which areas?

Table A.1 of DIN VDE V 0108-100-1 from 12/18 specifies the required operating times and which systems may be used for power supply.

Is emergency lighting also required outside buildings?

According to EN 1838, safety lighting must also be provided outside buildings up to a safe area.

What is the maximum number of SL/RZ luminaires that may be connected to one final circuit?

According to HD 60364-5-56, point 560.9.3, a maximum of 20 luminaires may be connected to one final circuit. The final circuits must not be loaded with more than 60% of the rated current of the protective device. This requirement also applies to self-contained luminaires.

Where does it say that the luminaires must comply with DIN EN 60598-2-22?

In DIN VDE V 0108-100-1 from 12/18, section 5.4.1.

What uniformity is required for emergency lighting?

According to EN 1838, the ratio of maximum to minimum illuminance must not exceed 40:1.

At what height above the floor must the safety lighting be measured?

- According to EN 1838, the measuring height is 2 cm above the floor.

- According to workplace regulation ASR A3.4/7, the measuring height is 20 cm above the floor.

What luminance must a pictogram have in mains operation and in battery operation?

According to DIN 4844 Part 1 of 06/12, the average luminance for mains operation must be at least 500cd/m². According to EN 1838, the luminance of the safety colour (green) must be at least 2 cd/m² in emergency lighting mode.

What uniformity / ratio must the luminance have?

According to EN 1838, the ratio of white luminance to green luminance must be at least 5:1, but must not be greater than 15:1.

What is the minimum height at which escape sign and emergency luminaires must be installed?

In accordance with EN 1838, at a minimum height of 2 m and max. 20° above the horizontal line of sight (see supplement to DIN EN 1838).

Which pictograms may be used?

All pictograms in accordance with ISO 7010 and ASR A1.3.

Can old and new pictograms be used in a building/object?

Only uniform pictograms should be used in a building/property.

Within what time must the safety lighting in a workplace be measurable?

According to DIN VDE V 0108-100-1 of 12/18 Table A.1, the required illuminance must be present after 15 s at the latest. For workplaces with special hazards, after 0.5 s.

What information from an emergency lighting system must be displayed at a central, suitable location?

According to DIN VDE V 0108-100-1 of 12/18, Section 5.4.2, the following information must be displayed:

- System ready for operation

- System faulty

- Supply from the backup power source/battery operation

Which tests must be carried out on battery-powered safety lighting systems?

- Daily visual inspection of the displays for correct function (in accordance with DIN VDE V 0108-100-1 from 12/18, section 6.4.2)

- Weekly functional test of the lights with battery connection (in accordance with DIN VDE V 0108-100-1 from 12/18, Para. 6.4.3)

- Monthly functional test of the lights with battery connection (in accordance with DIN VDE V 0108-100-1 from 12/18, section 6.4.4)

- Annual testing, including of the battery, including weekly and monthly testing as well as testing of the luminaires and battery over the full rated operating time (in accordance with DIN VDE V 0108-100-1 from 12/18, Para. 6.4.5)

Which standard must automatic test systems for safety lighting comply with?

They must comply with DIN EN 62034 in accordance with DIN VDE V 0108-100-1 from 12/18, Para. 5.4.3.

How long must the battery system continue to function during the annual endurance test before the battery is replaced?

According to DIN VDE V 0108-100-1 of 12/18, para. 6.4.5 a), the duration test must be carried out over the required rated operating time. If this is not achieved, the battery must be replaced.

Can luminaires with an ECG that is also suitable for 220V DC operation be connected to central power supply systems?

Many control gear units are labeled as being suitable for 220V DC operation. However, this does not mean that they are automatically suitable for connection to central power supply systems. Such lights must meet all the requirements of DIN 60598-2-22. For example, according to section 22.7.3, they must be equipped with a DC fuse to protect the light fitting. For these cases, SCHUCH supplies luminaires in "ZB design", with which you are guaranteed to be on the safe side.

Topic area LED

Can LED lights be switched indefinitely?

Frequent switching can damage the electronics and thus lead to an increased failure rate. According to the specifications of the International Electrotechnical Commission (IEC), it is assumed that outdoor luminaires are switched once a day and indoor luminaires are switched up to three times a day. If more frequent switching is required, this must be checked and approved by the luminaire manufacturer.

For frequent switching, we recommend using our versions with corridor function (DIMC). The corridor function enables unlimited switching of the luminaires. In corridor mode, the luminaires are not switched off but dimmed to 10%.

What is meant by system wattage?

The system power (also called rated power) is the input power of a luminaire in watts (W) in the undimmed state. This is made up of the power consumption of all electrical components of the luminaire.

What is meant by luminaire luminous flux?

Luminaire luminous flux (also known as rated luminous flux) is the luminous flux emitted by a new luminaire in lumens (lm). In contrast, the lamp or module luminous flux is the luminous flux emitted by a lamp or LED module. The luminaire luminous flux is the lamp or module luminous flux multiplied by the luminaire efficiency ratio (LOR). The luminaire operating efficiency (LOR) takes into account the efficiency losses caused by optics, cover glass, shading and deviating operating temperatures. Unlike for conventional luminaires, the luminaire operating efficiency is not specified for LED luminaires.

What tolerances must be expected for luminous flux and system output?

Rated values for luminous flux and connected load are subject to tolerances. Deviations in the single-digit percentage range are possible. According to IEC 62722-2-1, however, the luminous flux of a luminaire must not be more than 10% below the specified value and the connected load must not be more than 10% above the specified value.

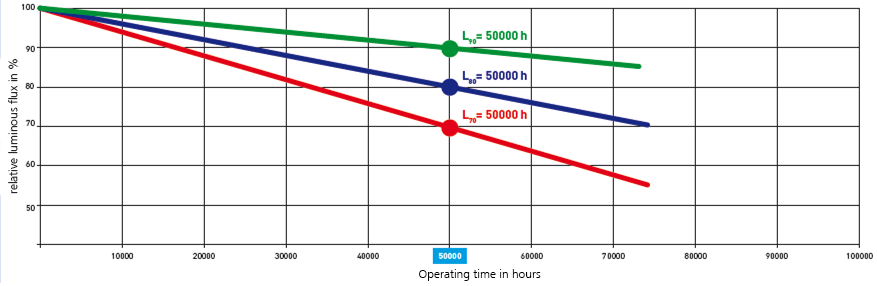

What do the service life specifications for LED lights mean?

The value Lx describes the time after the original luminous flux has decreased to a percentage value x. Typical values of x are 80 (L80) or 90 (L90). The service life specifications are based on defined test procedures. Failures of operating devices and the degree of soiling of the luminaire are not taken into account. The specified service life is an expected value, i.e. a statistical value and not a guaranteed property of the luminaire.

What level of luminous flux reduction (degradation) is to be expected with LED luminaires during their service life?

LEDs are semiconductor light sources. Over time, the number of defects in the semiconductor crystal increases depending on temperature and current density. Defects lead to non-radiative emissions. This leads to a decrease in luminous flux - also known as degradation. As shown in the adjacent diagram (source: ZVEI), the decrease in luminous flux over time is linear to a first approximation. The value of the decrease in luminous flux over the service life can be taken from the service life specification Lx. Lx > 100,000h, for example, stands for a reduction in luminous flux of 100% - x% after 100,000h. In the case of Lx = L80 this would be 20%, for L90 only 10% reduction in luminous flux.

Luminaires with a constant luminous flux function (CL) do not show any reduction in luminous flux over their service life. The luminous flux remains constant over the entire service life of the luminaire. See also

"What is meant by the term "constant luminous flux function".

May LED luminaires be operated above the specified maximum temperatures for short periods?

Luminaires are suitable for the specified maximum ambient temperature. If this temperature limit is observed during operation, the specified service life is achieved. As a rule of thumb, the service life of electronic components is halved if the temperature rises by 10K (Kelvin). Short-term operation at a higher ambient temperature is possible but will result in a reduction in service life. Please note that operation outside the permissible ambient temperatures will invalidate any warranty or guarantee claims.

What influence does the ambient temperature have on the service life of LED luminaires?

The service life of an LED light depends largely on the ambient temperature.

Low temperatures extend the service life of LEDs (in continuous operation). At very low temperatures, frequent switching significantly reduces the service life of the LEDs. We recommend our DIMC function here. Operation below the permissible minimum temperature of the luminaire leads to a significant reduction in the service life of all components.

High temperatures lead to faster degradation of the luminous flux. Operation above the maximum permissible temperature of the luminaire also reduces the service life of all components. Early failures become more likely.

Why does an LED luminaire with e.g. 3,500 lm replace a conventional 1x58W luminaire with 5,000 lm?

LED luminaires have integrated LED light sources. Accordingly, only the luminous flux emitted by the luminaire (luminaire luminous flux) is shown. Conventional luminaires, on the other hand, use a separate lamp. As different lamps can sometimes be used in a luminaire, the luminous flux of the respective lamp is shown (lamp luminous flux). Depending on the luminaire efficiency ratio (LOR), the luminaire has a lower luminaire luminous flux. If a fluorescent lamp with 5,000lm is used in a moisture-proof luminaire with an LOR of 0.7, the resulting luminaire luminous flux is 3,500lm. In this case, an LED luminaire with 3,500lm therefore replaces a conventional luminaire with a lamp that emits a luminous flux of 5,000lm.

What are the advantages of using luminaires with variably adjustable luminous flux (VARIO versions)?

Luminaires with adjustable luminous flux (VARIO) offer the option of setting the luminous flux to the required level almost continuously on site. Subsequent changes (e.g. for changes of use) are also possible. The use of a single version for different requirements also significantly simplifies stock-keeping.

What is the difference between a VARIO version and a VARIO NFC version?

VARIO versions have a DIP switch in the luminaire for almost infinitely variable adjustment of the luminous flux.

VARIO NFC versions offer the same advantages as VARIO versions, but are equipped with an NFC interface ("Near Field Communication") instead of a DIP switch, which enables contactless, almost infinitely variable adjustment of the luminous flux via an app (iOS/Android).

Can the luminous flux of a luminaire be changed retrospectively?

With our VARIO versions, subsequent changes to the luminous flux by the customer and thus adaptations to use are no problem. In all other cases, please contact us. As a rule, it is possible to change the luminous flux by programming the operating device (special hardware and software required).

How many LED lights can I connect to a miniature circuit breaker?

The information on the permissible number of LED lights that can be connected to a miniature circuit breaker (B or C characteristic) can be found in the data sheet for the respective light (see product pages on our website).

How many LED lights can I connect to an RCD or residual current circuit breaker?

There is no general answer to the maximum possible number of luminaires per RCCB. Normally, this is lower than the maximum number of luminaires per circuit breaker. For example, a 30mA RCCB may trip from 15mA. As EN60598 states that a luminaire may have a protective conductor current of up to 3.5mA, at least 4 luminaires (per RCD phase) are possible in any case. As a rule, the number is higher, especially for luminaires in protection class II, luminaires with low wattage and luminaires with only one built-in electronic ballast. We will be happy to provide you with the exact number of a luminaire type on request.

How many LED lights can I connect to a relay?

The number of LED lights permitted on a relay depends on the level of the inrush current pulse and its duration. It varies from operating device to operating device. We will be happy to provide the values for the relevant luminaire on request. This information can be used to select the appropriate relay.

Can control gear/ballasts and LED modules be replaced?

All SCHUCH luminaires (except the PRIMO XR gas-tight luminaire) are designed so that all components, including control gear and LED modules, can be easily replaced at the end of their service life or in the event of a defect. This is sustainable and environmentally friendly. However, the replacement may only be carried out by Schuch, a service technician commissioned by SCHUCH or a similarly qualified person in compliance with ESD protection measures. The replacement may only be carried out with components supplied or authorized by SCHUCH.

Attention: Many operating devices are programmed, i.e. replacing an operating device with an identical device does not automatically guarantee the desired function!

Many SCHUCH luminaires also use Zhaga-compliant LED modules. This makes the luminaires future-proof and ensures a high and long-term availability of spare parts. Zhaga is an international consortium of the lighting industry which standardizes LED modules, among other things.

Can LED retrofit lamps be used in conventional Schuch luminaires without any problems?

Explosion-proof luminaires must not be operated with LED retrofit lamps! The following applies to all other Schuch luminaires for fluorescent lamps with conventional ballasts: According to EN 60598, the lamps that may be used together with the luminaire must be specified on the type plate of a luminaire. When LED lamps are used, the luminaires no longer correspond to the version tested by us. This invalidates the CE declaration of conformity. Furthermore, the operation of luminaires with lamps not specified by us invalidates all warranty claims.

Irrespective of this, no problems are to be expected in practical operation if lamps tested in accordance with EN 62776 are used that are supplied with short-circuit starters and for which the manufacturer has complied with all applicable EU directives.

In the medium term, however, we recommend replacing existing luminaires with conventional ballasts with LED versions. As retrofit lamps in diffuser luminaires are located in a small enclosed space, heat builds up, which has a negative effect on lamp life. In lighting systems with higher ambient temperatures, this can result in unacceptably high internal temperatures. SCHUCH also supplies LED luminaires for higher ambient temperatures up to +70°C. Please get in touch with us.

Apart from better thermal management, LED luminaires are also more efficient than luminaires with LED retrofit lamps. The retrofit lamp must be evaluated together with the luminaire as a system, the specified luminous flux of the lamp is not comparable with the luminaire luminous flux of an LED luminaire, see also "Why does an LED luminaire with e.g. 3,500 lm replace a conventional luminaire 1x58W with 5,000 lm?"

topic area light management

Can outdoor luminaires also be retrofitted with a light management system?

Yes, but only if they have been designed as RFL luminaires ("Ready for Light Management Systems"). One or two Zhaga-compliant bases integrated into the luminaire housing allow the required components such as controllers, radio antenna and sensors to be retrofitted without tools. The standardization of the bases in accordance with Zhaga Book 18 means that they are not tied to a specific light management system.

What restrictions must be expected when using infrared and radar sensors outdoors?

Infrared sensors require a temperature difference in order to detect objects. Radar sensors, on the other hand, do not require temperature differences in order to detect objects. For both sensors, it is important that the environment is as static as possible without movement (e.g. branches in the wind, rain), otherwise unwanted false triggering may occur. Furthermore, objects (e.g. branches) can obscure the sensors and thus limit object detection.

What is the range of the LIMAS or RFL sensors?

The range of sensors depends on the corresponding mounting height of the luminaires. The maximum mounting height for LMS IR luminaires and RFL accessories is 12m.

On which radio frequencies do LIMAS and RFL products operate?

LIMAS luminaires and RFL accessories operate at a radio frequency of 2.4 GHz. An automated mesh network ensures stable radio communication.

Can these radio frequencies affect/interfere with other products in the company?

LIMAS luminaires and RFL accessories operate with an extremely low transmission power of <10mW. An interfering influence on other radio systems and transmission masts is not to be expected. However, radio systems and transmitter masts can have a negative impact on the transmission and reception properties of luminaires with light management systems. If luminaires with light management systems are to be installed in the vicinity of radio systems, please contact us.

How long can the DALI cable be?

A DALI cable with a cross-section of 1.5mm² may be a maximum of 300m long.

Can more than 300m of cable length be bridged with DALI?

Yes, either with a larger cable cross-section or with a DALI repeater. With a DALI repeater, a further 300m is possible with a cross-section of 1.5mm².

What is the difference between DALI and DALI-2?

DALI-2 extends and improves the DALI standard. With DALI-2, not only ballasts but also control devices (controllers), sensors and operating units are now part of the standard. More feedback can be requested from LED ballasts and better interoperability (through mandatory certification) can also be guaranteed. DALI-2 extends the standard with some additional functions, such as Tunable White and Wireless Connectivity (DALI+).

Are LIMAS Line lighting management controllers DALI-2 capable?

Yes, both DALI and DALI-2 are supported.

Can sensors from third-party manufacturers also be integrated into LIMAS Line?

Yes, some sensors from third-party manufacturers have been approved for the systems. Please contact us.

Can LIMAS Line be integrated into a higher-level building management system?

Yes, LIMAS Line Pro can communicate with other systems via the BACNET interface.

Can self-contained emergency luminaires be monitored with LIMAS Line?

Yes, LIMAS Line PRO can monitor and control up to 192 self-contained emergency luminaires.

Can several LIMAS Line systems be interconnected?

Yes, up to 100 controllers can be interconnected with LIMAS Line PRO.

Can the time for the function and duration test of a self-contained emergency luminaire be specified?

Yes, with our LIMAS Line PRO light management system, the exact time can be set and carried out fully automatically on any day at any time.

How are the logs of the tests carried out on the self-contained emergency luminaires made available or displayed?

The results of function, operating time and control tests as well as events and user information are documented in the system's test log over a legally defined period. The test logbook entries are sorted chronologically. You can export the test logbook as a PDF or XML file.

Can I connect conventional switches to the LIMAS Line systems?

Yes, but this requires an analog to DALI converter.

What types of sensors can be integrated into LIMAS Line systems?

Infrared sensors (PIR), HF sensors and daylight sensors can be integrated.

Can RGB(W) and Tunable White luminaires be controlled?

Yes, as the LIMAS Line systems are Device Type 8 (DT8) capable, such luminaires can also be controlled with RGB(W) and Tunable White luminaires.

Is a continuous Internet connection necessary to operate the systems?

LIMAS Line BASIC - No continuous internet connection is required, only for the one-off download of the app.

LIMAS Line PRO - No continuous internet connection is required.

LIMAS / RFL - The luminaires in the LMS version and accessories such as the LIMAS HUB do not require an internet connection and work completely independently once they have been set up. A permanent Internet connection is only required when using a gateway.

Ex-Protected

Ex-Protected Outdoor

Outdoor Indoor

Indoor Emergency

Emergency LED

LED Light Management

Light Management